Stress measurement

Why is stress measurement imperative?

Any mechanical part and any material have stresses, which can lead to deformation, the formation of cracks or even rupture. The presence of these stresses is mainly due to the manufacturing or assembly processes. It can evolve and vary according to the type of process :

- Machining

- Cold rolling

- Casting

- Hot rolling

- Oxycutting

- Welding

- Surface treatment

Some structures are subject to increasingly trying conditions, and therefore it is of paramount importance to know the magnitude of these stresses and to follow up their evolution over time. This helps predict fatigue of mechanical parts and materials. You will be able to prevent potential risks, ensure optimum safety and quality, and achieve significant savings.

How to measure the stresses ?

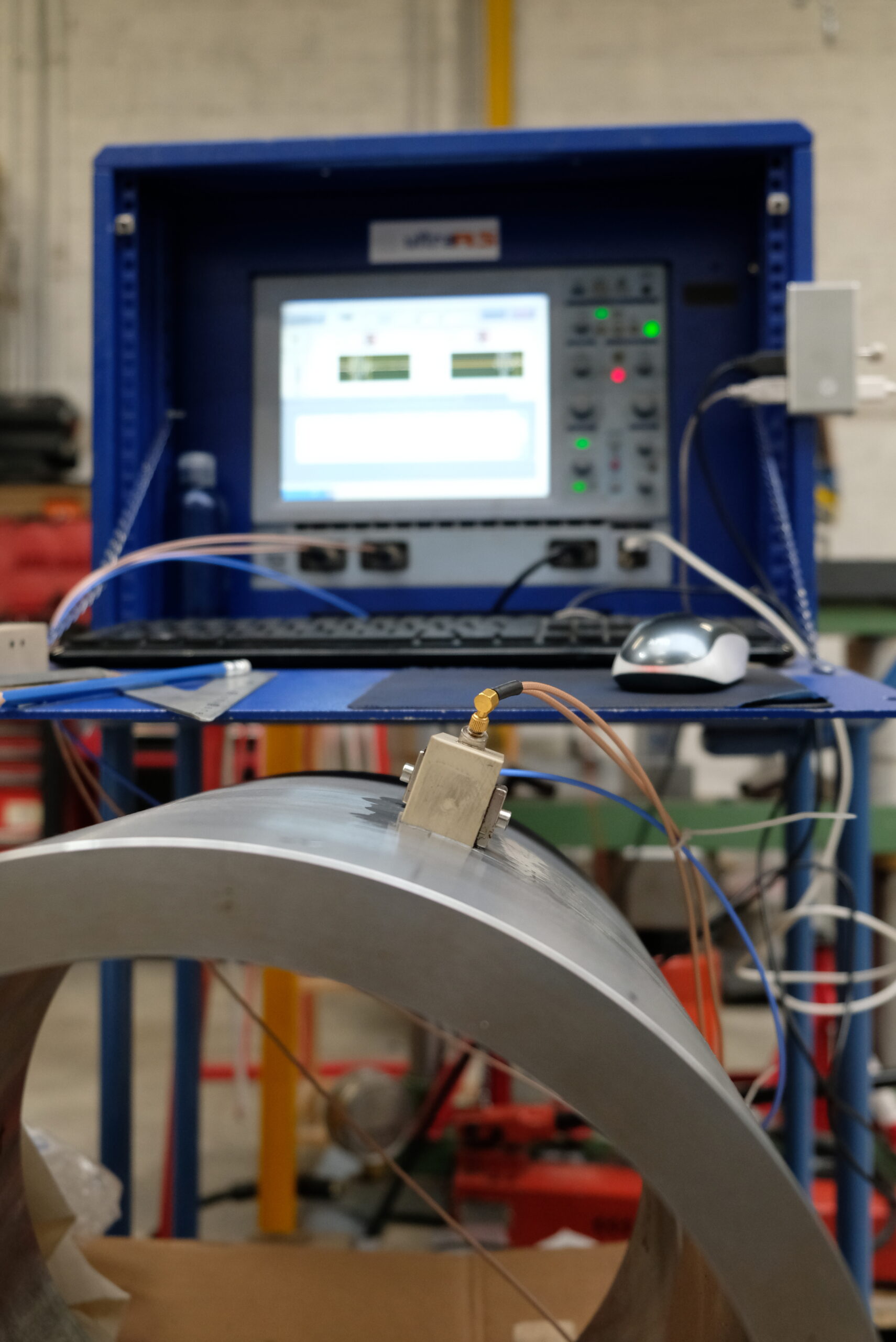

We offer manufacturers efficient and accurate stress analysis tools in mechanical components.

Entrust us the control of your mechanical pieces on your site.

We will provide you with the following services:

- Study and set up of the specifications with client collaboration;

- Development of the measuring devices depending on customer specification;

- Qualification of ultrasonic stress measurement method;

- Control of parts and interpretation of the results;

- Documentation and reporting.

Ultra RS

We develop solutions for non-destructive testing and material characterization by ultrasound. Industrialists of all kinds, to ensure the quality, reliability and safety of your production and assembly lines and to achieve significant savings, contact us!

Solutions

16 rue de la Prairie,

77700, BAILLY-ROMAINVILLIERS

+33 (0)1 83 38 94 72

ISO 9001 Certified